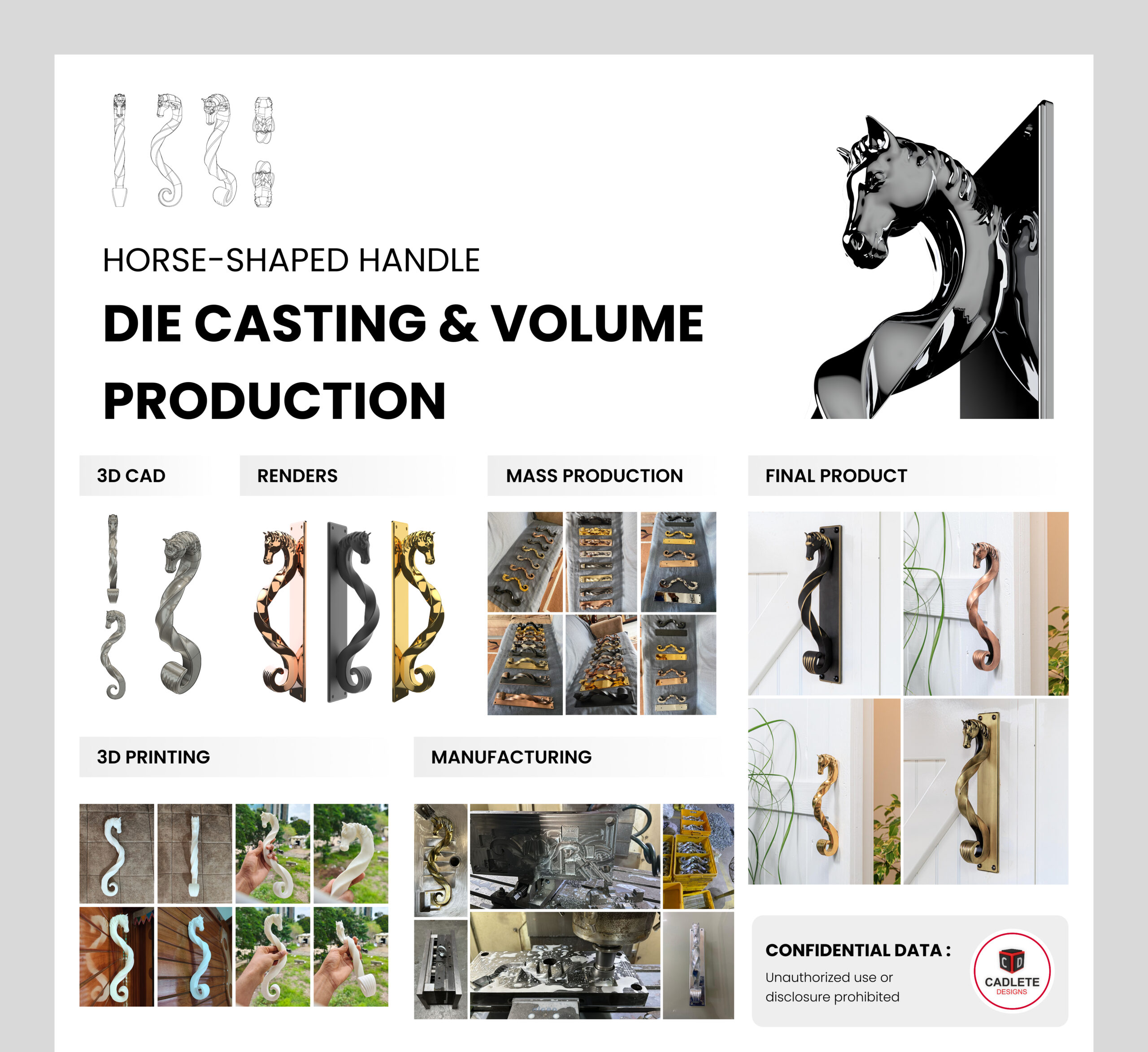

About this project

This project involved redesigning and mass-producing a premium horse-shaped handle for a USA-based client who wanted to enhance the realism and visual appeal of their existing product. The goal was to create a handle that felt more organic, detailed, and lifelike, while maintaining strength and manufacturability through die casting.

What We Did:

- Design Optimization: The client provided an existing handle design, which we carefully refined to make the horse face and tail flow naturally, taking inspiration from both real horse anatomy and the curves of a seahorse tail for an elegant form.

- Concept Sketching & CAD Modeling: We started with concept sketches to explore organic proportions, followed by advanced surface modeling to achieve smooth, sculpted details suitable for die casting.

- Tooling & Manufacturing: Once the design was finalized, we developed the die-casting mold and successfully executed volume production with high dimensional accuracy and finish quality.

- Premium Finishing: Each handle underwent PVD coating in over 10 unique metallic color finishes, enhancing its luxury appeal and durability.

- End-to-End Support: We provided DDP (Delivered Duty Paid) logistics service, ensuring seamless delivery to the client’s doorstep. The handles are now booming in the USA market, earning great feedback for both aesthetics and build quality.

This project reflects our expertise in blending artistry with engineering precision, from concept design to global-scale production.