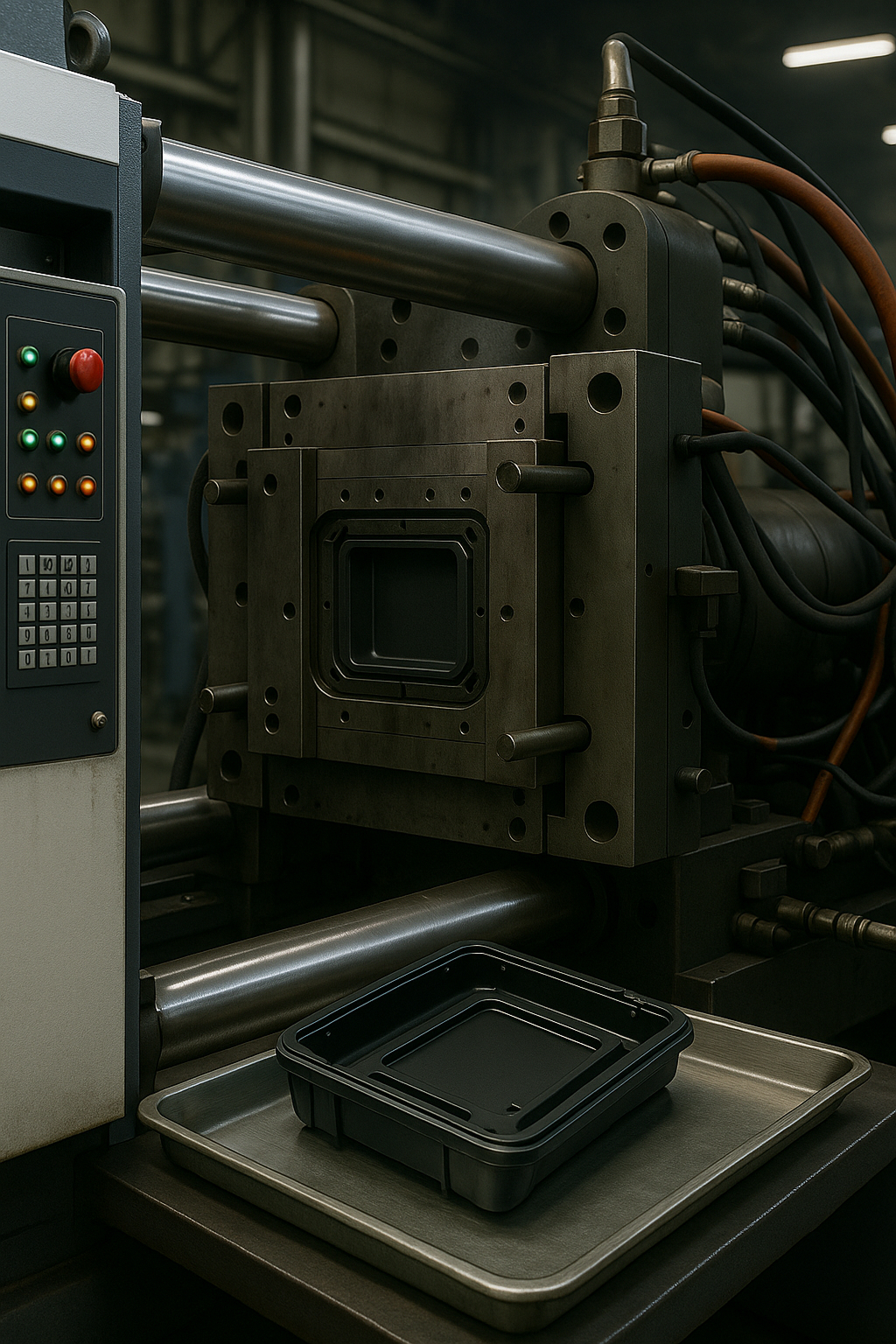

Injection Molding

We turn your 3D ideas into precise, durable, and cost effective plastic parts. From DFM and tooling to validation, our expert injection molding delivers fast & production-ready solutions, from prototype to mass manufacturing.

Precision Plastic Manufacturing Solutions

We don’t just mold plastic, we mold perfection

Why CADLETE for Injection Molding?

-

120+ Successful Mold Creations

We have designed and delivered over 120 custom molds, ensuring precision and efficiency for every project. -

Tooling & Mold Design Expertise

In-house team for DFM, mold flow analysis, and tooling validation. -

Fast Turnaround

Rapid prototyping to production tooling with short lead times. -

Material Selection Guidance

Support for ABS, PP, PC, Nylon, TPU, Silicon, and more. -

Tight Tolerances & Quality Assurance

We design for durability, precision, and part repeatability. -

Global Manufacturing Network

Manufacturing support from India and overseas facilities for cost efficiency and flexibility.